OUR FORESTS

Our Forestry and Resin Division manages planting, resin tapping , and wood for about 55,000 hectares distributed among our own areas, partnerships, leasing, and forest partnership.

FORESTRY & MANAGEMENT

The first step in establishing the forest is the choice of the genetic material that will be planted. Our Genetic Improvement Program was started in the 1980s, responsible for producing superior genetic materials of various species adapted to the country’s diverse climatic conditions. Our Forestry Research Program promotes continuous improvements in processes and products, both in seedling production and forest management. The result is highly productive, healthy forests.

In the forestry implantation and maintenance phases, we follow silviculture and management practices established in the literature, adjusted by our Forestry Research Program, and approved by the FSC sieve:

FORESTRY

CLEANING THE AREA:

The area where the forest will be planted needs to be free of weed competition. This can be done via mowing and or herbicide application.

Combat ants:

It is usually done using bait-formicides, in a localized way.

SUBSOILING/SHOEING:

Where it is not possible to subsoil, we do hand-troweling. In this case, we do the beaconing operation first, to ensure that the correct spacing is followed. Dimples are opened to accommodate the seedlings for planting.

PLANTING:

When planting, make sure that the root ball does not bend inside the hole. The stem of the seedling should be level with the pit, neither drowned nor exposed.

REPLANTS:

It should be done around three months after planting.

FOREST MANAGEMENT

CLEANING THE AREA:

Combat ants:

The combat is usually done using bait-formicides, in a localized way, when damage is identified in the forest.

Thinning:

Pruning:

FOREST RESEARCH

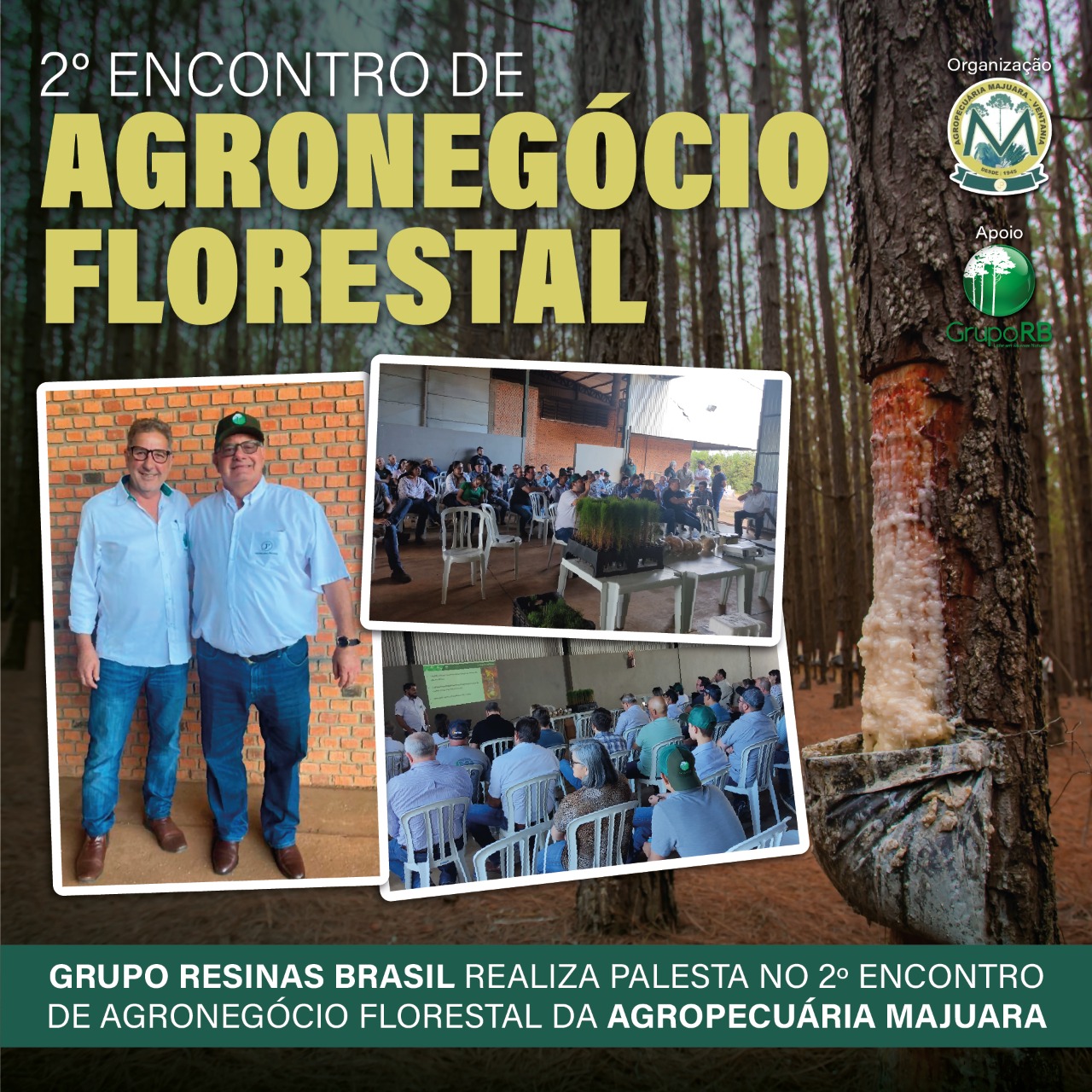

An important action for the success of a forestry project is the choice of the seedling that will be planted. Since the 80’s, Grupo RB has developed Research and Genetic Improvement activities aiming to increase the productivity and quality of Pinus spp. resin gum. The forest improvement program has well-defined strategies, planned in the short and long term, to obtain the desired genetic materials.

Thanks to the high genetic diversity of the Pinus genus, the improvement program has been able to manipulate the characteristics of interest by means of mass selection, controlled crossbreeding and hybridization, progeny and provenance testing, always seeking to obtain genetic materials adapted to meet the most diverse purposes and environments. This action has been providing gains in the quality of the raw material, increasing resistance to pests and diseases, besides the increase in production associated with the lowest possible cost. Currently, the Forestry Research Department develops work in the areas of biotechnology, genetic improvement, cloning, nursery, resin tapping, forest management, and nutrition.

VIVEIRO JAÓ

RB Group seeks the production of high quality seedlings for the formation of forest plantations. Besides being able to offer its customers improved seedlings for resin and wood production, it also offers the result of its Forestry Research and Development. The RB Group’s nursery has a team specialized in genetic improvement, responsible for selecting and indicating new materials for planting. This action promotes the increase in the productivity of resin gum and wood from forest plantations. A forest planted with the right genetic material for resin production can have productivity of more than 4 kg/tree/year. The resin provides periodic income, in addition to the income from the wood at the end of the cycle. The annual production capacity of the Jaó Nursery is 15 million Pinus spp. seedlings.

VIVEIRO JAÓ

RB Group seeks the production of high quality seedlings for the formation of forest plantations. Besides being able to offer its customers improved seedlings for resin and wood production, it also offers the result of its Forestry Research and Development. The RB Group’s nursery has a team specialized in genetic improvement, responsible for selecting and indicating new materials for planting. This action promotes the increase in the productivity of resin gum and wood from forest plantations. A forest planted with the right genetic material for resin production can have productivity of more than 4 kg/tree/year. The resin provides periodic income, in addition to the income from the wood at the end of the cycle. The annual production capacity of the Jaó Nursery is 15 million Pinus spp. seedlings.

With over 35 years of investment in research and development, our exclusive Genetic Improvement Program has excelled in creating more productive and profitable pine forests. Achieving superior economic and operational results throughout the forestry cycle.

The forests under the RB Group's management, in addition to our genetically improved seedlings, are subjected to strict silvicultural management in order to maximize the production of gum resin and high-quality wood. Our FSC®-certified forestry base is subject to strict silvicultural management, guaranteeing the highest standards of sustainability for our forests, which are environmentally appropriate, socially beneficial and economically viable.

The resining tapping process begins with the groove in the tree trunk and later the gum resin is collected, to supply the factories of the RB Group.

At the end of the resining cycle, the trees are felled to replant the new forest. Part of the wood produced is used to sell and supply Itabox, the RB Group's furniture industry.

The RB Group, recognized as a global leader in Natural Resins, has 15 industrial units, 08 of which are Forest Stewardship Council® (FSC) Chain of Custody certified. Present in Brazil and Europe, our industrial facilities stand out for their technological efficiency, which enables us to offer the highest quality products to our customers around the world.

Our food sector, represented by Sweet Gum and Cafosa, makes us the largest producer of chewing gum base in the world. Committed to our customers' satisfaction, we incorporate the most advanced and safest technologies available in the chewing gum industry, which allows us to provide services and a wide variety of products with superior quality and performance.

by

by