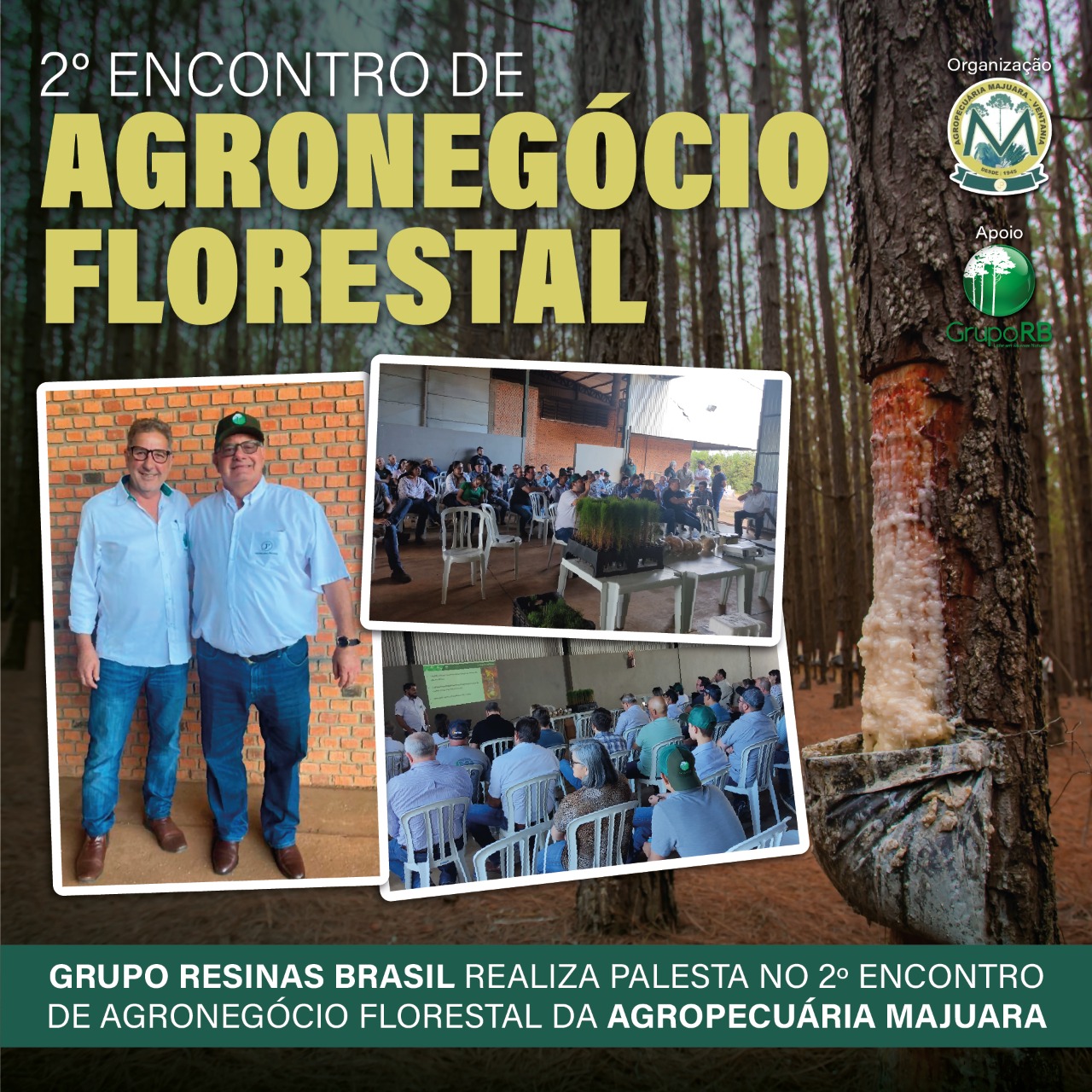

THE RB GROUP RESIN TAPPING

The gum resin extracted from pine forests is the main raw material of RB group, a natural product that supplies our industrial units, where rosin and turpentine are produced, the main derivatives of gum resin.

In your daily life, you have probably already used many products made from gum rosin, used in the chemical, food, cosmetic and pharmaceutical industries. We can cite as examples, paints, varnishes, adhesives, chewing gum, depilatory waxes, perfume essences, ointments for muscular pains, camphors, and many other products.

But for you to have access to these products made from gum resin, it took years of research and a lot of

and a lot of field work.

Currently, the traditional way of extracting gum resin in the forests is done manually, a practically handcrafted work, done on each pine tree.

RB Group has conquered the market leadership in natural resins, with a lot of investment in the resin tapping teams,

we are currently the largest employers in the sector.

The whole resin tapping process is performed by a specialized field team, constantly trained for the adequate conduction of the procedures of gutting, collecting and storing the gum resin.

The quality of RB’s gum resin has conquered the market recognition due to the development of the best extraction and transport techniques in its resin tapping operations.

Aiming at the optimization of this process, besides the traditional removal in drums, our resin tapping is a pioneer in the mechanized collection

known as transshipment, done by hydraulic buckets for the transportation of the collected resins to the factories.

Learn more about the resin tapping operations below:

What is Resin Tapping

Resin tapping consists in extracting gum resin from trees of the Pinus genus, by means of small periodic incisions in the outer part of the trunk. Generally, the activity is initiated in stands with an average DBH greater than 18 cm. The species with the highest potential for productivity in Brazil are Pinus elliottii, Pinus caribaea-hondurensis, Pinus caribaea-caribaea, Pinus caribaea-bahamensis, Pinus oocarpa, and Pinus elliottii hybrids.

Each face produces approximately 4.5 of resin per year.

However, some selected plants in the breeding program produce up to 10 kg of resin per year, showing a great potential for selection and genetic improvement for this characteristic.

Productivity is influenced by genetic and edaphoclimatic factors of each region.

Our Differential:

- Tradition in the market, our resin tapping method is already operationally consolidated and recognized by several companies in the forestry sector;

- Increase of the local economy, resin tapping anticipates the forest revenues, generating results equal or even superior to those obtained only with the sale of wood;

- Sustainable Planted Forest, it does not generate any type of residue or environmental liability to the location where the gum resin is produced;

- It avoids the rural exodus, contributing to the settlement of men in the countryside;

- Each face produces approximately 4.5kg of gum resin per year;

- It boosts the local economy, the resin tapping anticipates the forest revenues, generating equal or even higher results than those obtained only with the sale of wood.

Forest Cycle

FOREST IMPLEMENTATION

Preparation of the area and planting of pine seedlings. After planting, it is essential to perform the cultural treatments of cutting and ant control.

PREPARATION FOR RESIN TAPPING

Aiming at the best performance of the resin tapping activity, during the initial 7 years the forest maintenance should be carried out. At this stage the ideal is that the branches are above the height of the panel, depending on the planting spacing is recommended thinning, and it is also essential to perform pruning.

RESIN TAPPING STARTS

Near the tenth year the forest is already in ideal conditions to start the first resin tapping season, in general, the gum resin extraction can be conducted during 10 consecutive years (harvests).

TIMBER HARVEST

At the end of resin tapping the forest will be about 20 years old, ready for cutting and planting pine seedlings, starting a new forest cycle.

Estimates per hectare in the cycle: 500 – 700 m3 of wood and 30 – 50 tons of gum resin

ALREADY KNOWS THE PROCESS OF RESIN tapping?

Learn about our resin tapping process in a simple and objective way.

Installing the Sachet

The method uses a tool called a scriber, which opens a horizontal line on the tree, which will result in the base for positioning the bag. At this point, a groove is opened, a stimulating vegetable-based paste is applied, and the bag is placed.

Stria

The resin tapping harvest starts in October and lasts until September of the next year. During the spring, summer, and fall seasons, the grooving and collection of the gum resin takes place; and in the winter, the finishing and preparation of the next harvest. As the harvest progresses, the grooves advance on the panel one after the other, requiring a change in the format and tools used. Usually, the width is kept between 2 and 2.5cm and 20cm in length:

NORMAL

MACHETE OR DIAGONAL

Following 1,40m to 1,60m

V-SHAPED

Following from 1,60m up to 2,20m

Collection

This is the activity of collecting the resin stored in the bag. This collection can be semi-mechanized or manual. It is done from 2 to 4 times a year in each tree, keeping a continuous flow of collection.

- Semi-mechanized collection: used in large areas with specific teams for this activity, where the topography of the terrain allows for mechanization;

- Manual collection: used in smaller areas or with irregular topography.

Sack climbing

Activity performed whenever the groove is far from the panel. It usually occurs during the harvest, and the panel is raised to a maximum height of 1.2 meters.

Transportation Forest - Factory

Besides the traditional transportation of drums, our group is a pioneer in the transshipment and transportation of gum resin in containers in the “Roll-On-Roll-Off” system to the manufacturing units.

In our logistics operations, we count on several road transport modalities, all in compliance with the Law 9.503/97 of the Brazilian Traffic Code.

by

by